-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Reels

-

Статьи пользователей

-

Funding

-

Jobs

-

Courses

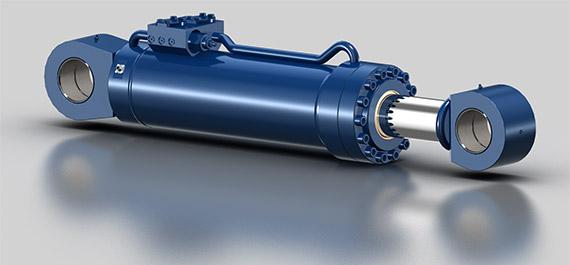

Growth Outlook for the Global Telescopic Hydraulic Cylinders Market

Introduction

The Telescopic Hydraulic Cylinders Market is witnessing steady growth as industries increasingly adopt compact, high-stroke hydraulic solutions for lifting, dumping, and material-handling applications. Telescopic hydraulic cylinders consist of multiple nested stages that extend sequentially, providing a longer stroke from a shorter retracted length. This makes them ideal for equipment where long extension is needed but space is limited. These cylinders are widely used in dump trucks, agricultural machinery, refuse vehicles, construction equipment, cranes, mining machines, and industrial handling systems. As infrastructure development, mechanized agriculture, logistics, and waste management activities increase across global markets, demand for reliable and high-performance telescopic cylinders continues to surge. Manufacturers are focusing on durable designs, leakage-resistant components, improved sealing, and advanced materials to enhance load capacity, efficiency, and lifecycle performance.

Market Drivers

Infrastructure expansion and construction investments are key drivers of telescopic hydraulic cylinder adoption globally. Growing deployment of dump trucks, tipper trucks, and mobile cranes boosts the demand for multi-stage cylinders capable of lifting heavy loads efficiently within compact dimensions. Mechanization in agriculture is increasing cylinder use in harvesters, loaders, and trailer lifting systems. Rapid urbanization and rising waste-collection needs fuel adoption in refuse trucks and compaction units. Growth in mining and quarry operations also strengthens demand due to heavy-duty equipment requirements. Industrial automation and material-handling modernization have additionally supported adoption in factory logistics and warehousing solutions. Advancements in seals, chrome-plated stages, and wear-resistant coatings are improving cylinder reliability and performance. OEM collaborations with hydraulic system integrators further accelerate market development.

Market Challenges

Telescopic hydraulic cylinders face challenges related to high manufacturing complexity and cost. Multi-stage designs require precision machining and robust sealing to prevent leakage, which increases production expense. Maintenance and repair of telescopic cylinders can be complex due to internal components that require expert servicing. Hydraulic fluid leakage and contamination risk remain concerns, impacting operational efficiency and environmental compliance. Longer lead times for custom-engineered cylinders create supply bottlenecks for OEMs. Raw material price fluctuations—especially for steel, surface-coating chemicals, and sealing components—affect product pricing. Competition from alternative lifting technologies, such as electric actuators for lighter applications, may constrain growth in some segments. Ensuring durability under harsh conditions—including construction dust, corrosive mining environments, and extreme weather—remains a continuous engineering challenge.

Market Opportunities

Product innovation and material advancements present significant growth opportunities. Lightweight, corrosion-resistant materials such as advanced alloys, composite coatings, and improved surface treatments can enhance performance and reduce maintenance. Integration of intelligent sensors for stroke measurement, load monitoring, and predictive maintenance can create “smart hydraulic cylinders” suitable for Industry 4.0-driven equipment. The rising use of hydraulic automation in agriculture, waste management, and municipal machinery offers scope for cylinder standardization and modular design systems. Electric-hydraulic hybrid systems can improve energy efficiency and reduce fuel consumption in heavy vehicles. Emerging markets in Asia-Pacific, Latin America, and Africa offer untapped potential due to growing infrastructure spending, industrialization, and municipal development programs. Aftermarket services, refurbishment programs, and distribution expansion also create profitable business models for cylinder manufacturers.

Regional Insights

North America and Europe hold significant market share due to established construction, waste management, and agricultural machinery sectors. The U.S. and Canada show strong adoption in dump trucks, forestry equipment, and industrial material-handling. Europe maintains high standards for hydraulic system efficiency, safety, and durability across Germany, the UK, Italy, and France. Asia-Pacific is the fastest-growing region, led by China, India, Japan, and South Korea with high infrastructure investments, growing mining operations, and rapid mechanization of agriculture. Latin America, especially Brazil and Mexico, is increasing demand through agricultural equipment and construction fleet modernization. The Middle East & Africa markets are expanding with large-scale infrastructure, mining, and oilfield projects that depend on heavy machinery using telescopic cylinders.

Future Outlook

The future of the Telescopic Hydraulic Cylinders Market will be shaped by technological upgrades, sustainability, and smart hydraulics integration. Design focus will shift toward energy-efficient systems with low oil consumption and improved sealing to reduce leakages. Sensor-enabled and IoT-connected hydraulic cylinders will support predictive maintenance, lifecycle monitoring, and integration with telematics platforms for fleet management. Eco-friendly hydraulic fluids and enhanced surface-coating technologies will improve product longevity and environmental performance. Manufacturers will strengthen localization of production and component sourcing to reduce supply-chain dependency. Customizable multi-stage cylinder platforms for electric and hybrid equipment will emerge as OEMs transition to more sustainable machinery. By the next decade, telescopic cylinders will continue evolving to deliver higher load capacities, longer life cycles, and data-enabled performance optimization.

Conclusion

The Telescopic Hydraulic Cylinders Market is poised for sustained growth as industries invest in reliable, compact, and high-performance lifting solutions. While challenges such as cost, maintenance complexity, and leakage prevention remain, innovation in materials, sealing systems, and smart monitoring technologies will drive product evolution. Growing infrastructure development, mechanized agriculture, and industrial modernization across global regions offer strong growth potential. Companies that focus on durability, efficiency, and smart hydraulic integration will lead the market, delivering next-generation telescopic cylinders that support high-performance machinery across sectors.

- Art

- Crafts

- Dance

- Wellness

- Movie & Television

- Adult Entertainment

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Business & Finance

- Religion

- Shopping

- Sports

- Theater

- Drinks

- Другое