Advantages Of Choosing A Reliable Vertical Packaging Machine Today

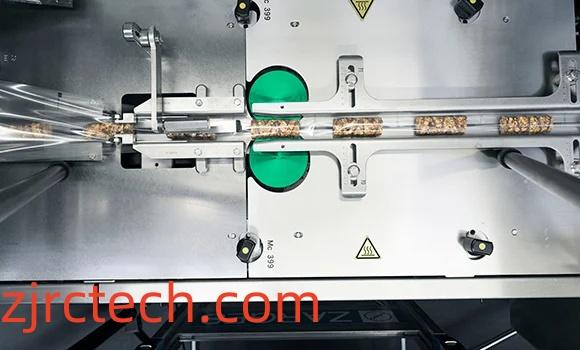

In modern production environments, the Vertical Packaging Machine has gained increasing attention for its role in transforming how goods are packed and delivered to consumers. This equipment offers a practical solution for industries that require speed, consistency, and adaptability across different product categories.

The primary advantage of using vertical packaging equipment lies in its efficient use of space and resources. By operating in an upright configuration, it allows manufacturers to optimize floor areas while still achieving high throughput. This makes it suitable for industries ranging from food processing to pharmaceuticals, where both space and efficiency are critical.

Another important factor is consistency. Automated packaging systems are designed to minimize human error, ensuring that every product is sealed and packed in a uniform manner. This not only enhances the appearance of the final product but also helps maintain quality standards across entire production lines.

Flexibility is also a defining feature. Modern systems can handle a variety of packaging materials, including films and laminates, and are adjustable to different product sizes and weights. This versatility allows businesses to adapt quickly to market changes without needing multiple machines.

From an operational perspective, these machines also reduce the need for extensive manual labor. By automating repetitive packaging tasks, companies can reallocate human resources to more strategic areas of their operations. In addition, automation reduces the risk of workplace injuries associated with repetitive manual work.

Sustainability is becoming a significant concern for many manufacturers, and automated packaging equipment can contribute positively in this area. By using precise measuring systems and reducing excess material use, these machines support businesses in achieving their environmental goals.

Maintenance and monitoring are made easier through the integration of digital technologies. Many modern systems come equipped with smart sensors that can detect irregularities early, allowing technicians to address issues before they become costly breakdowns. This proactive approach minimizes downtime and helps ensure continuous production.

In conclusion, investing in vertical packaging technology is not just about streamlining operations but also about creating long-term value. With growing demands for efficiency, quality, and sustainability, such equipment provides industries with a tool that adapts to both current and future challenges.

For more insights, visit https://www.zjrctech.com/

- Art

- Crafts

- Dance

- Wellness

- Movie & Television

- Adult Entertainment

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Business & Finance

- Religion

- Shopping

- Sports

- Theater

- Drinks

- Outro