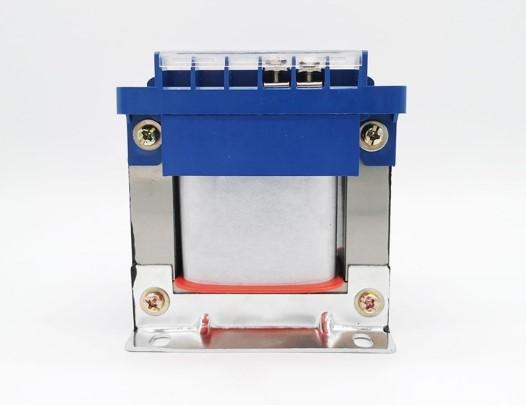

Nbcbdz BK Control Transformer Factory Supports Industrial Power Needs

In modern electrical engineering, the presence of a BK Control Transformer Factory highlights the importance of specialized production in meeting diverse industrial demands. These transformers are essential components in systems where stable voltage and reliable power conversion are required. They are particularly suited for environments such as machine tools, automation equipment, and precision machinery that depend on consistent performance.

The significance of these transformers lies in their role of stepping down or isolating voltage for safe and efficient use. Unlike power transformers that are primarily designed for large-scale energy transmission, control transformers focus on supplying devices and circuits that demand stable current at lower voltages. Their design ensures that electrical equipment operates smoothly, protecting sensitive components from fluctuations that could otherwise disrupt production or cause damage.

Factories that produce these units rely heavily on strict quality control and advanced engineering. Each transformer must undergo rigorous testing to ensure it meets performance requirements, safety standards, and efficiency targets. From the choice of core material to the winding process, every step in production contributes to reliability. This manufacturing discipline provides industries with confidence that their systems will remain operational under demanding conditions.

Energy efficiency also plays a critical role in transformer design. As businesses increasingly focus on reducing energy losses and operational costs, transformers that balance durability with energy savings are becoming essential. The use of advanced insulation materials and optimized coil configurations allows these transformers to function effectively while minimizing wasted energy.

Another strength is their adaptability. Control transformers can be applied across a range of industries, from industrial automation to transportation and renewable energy. This versatility makes them a valuable choice for companies looking to maintain flexibility in their operations while keeping costs manageable. The ability to customize transformers for specific applications further increases their usefulness, as factories can provide tailored solutions to meet unique requirements.

Safety remains an integral consideration. By delivering a stable output and isolating control circuits, these transformers enhance workplace safety and reduce the likelihood of electrical hazards. Workers and systems alike benefit from this protective feature, creating an environment that supports both productivity and compliance with safety standards.

In conclusion, control transformers are not only reliable components but also enablers of efficient and safe industrial systems. Their role in protecting equipment, reducing energy losses, and ensuring operational stability makes them a cornerstone of modern production. A dedicated factory ensures that industries continue to have access to transformers that are designed with precision, durability, and safety in mind.

For further details, visit https://www.nbcbdz.com/product/low-frequency-transformer/

- Art

- Crafts

- Dance

- Wellness

- Movie & Television

- Adult Entertainment

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Business & Finance

- Religion

- Shopping

- Sports

- Theater

- Drinks

- Other